Get the prototype done and setup China supply chain at the same time.

FDM(Fused Deposition Modeling)

: Done by heating and fusing ABS or PLA material.Pro: Less deformation

Con: Rough Surface, low precision 0.2-0.3mm

Size Limit: 25.2 L x 19.9 W x 15.0 H cm(Perunit)

CNC Machining:

Done by cutting (milling, turning, grinding) the materialPro: Very high precision, Very good surface, High strength

Con: Cannot make complex shapes

SLS (Selected Laser Sintering)

: Done by laser sintering of material powers。Pro: High strength, wide choice of materials: metail, ceramic, plastic

Con: Porous surface, Easy to deform

We can make prototype by SLS, please email us at contact@china-plasticmolding.com

3D Printing

: Done by laying powder and glue, then putting in layer after layer like a printer.Pro: Fast and low cost, Can add color

Con: Low strength

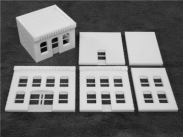

3D Printing + CNC Machining + Assembly