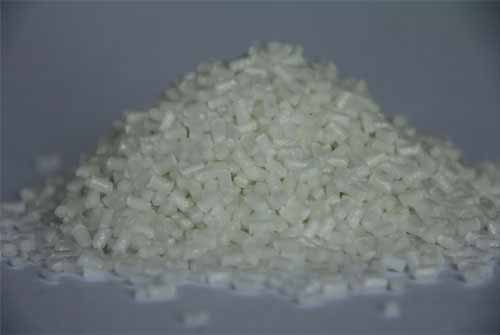

GF REINFORCED PC

The fatigue strength, tensile strength, flexural strength, elastic modulus and other mechanical properties of PC material are significantly improved by adding glass fiber. The heat resistance of PC material is greatly improved, and the forming shrinkage is small.

Glass fiber reinforced PC material has excellent toughness, strength, stress cracking resistance, heat resistance, glossiness, plating and spraying properties. It can be modified for flame retardant and strengthening. It can be customized according to the specific needs of customers. It can be made into glass fiber reinforced flame retardant PC, halogen-free flame retardant PC, weatherproof PC, glass fiber reinforced flame retardant PC/ABS alloy, general heat-resistant PC/ABS alloy, halogen-free flame retardant PC/ABS alloy, halogen-free flame retardant PC/ABS alloy, etc.

Glass fiber reinforced PC material has strength, rigidity and dimensional stability, and improves stress cracking. It is widely used in the fields of machinery, instrumentation, electrical appliances, transportation and other fields to manufacture bearing cages, guideways, gears, equipment shells, electronic computer parts, precision instrument parts, distribution boards, electric tool shells, automobile parts, aircraft parts, bicycle parts and Yu. Helmets for sailors, etc.Detailed understanding can be done through online or telephone counseling to solve your problems.

| Glass fiber reinforced PC | Product number | Product Features | The main purpose |

|---|---|---|---|

| PC+10%GF | 通用 | 音响支架、汽车、家用电器等 | |

| FRPC+10%GF | V-0级无卤阻燃 | 胶框 | |

| PC+20%GF | 通用 | 音响支架、汽车、家用电器等 | |

| PC+30%GF | 高刚性 | 音响支架、汽车、家用电器等 | |

| FRPC | V-0级无卤阻燃 | 电子电器部件 |

| ITEM | UNIT | STANDARD | H17N26PC/G10 | J17D02PC/G10 | A11801PC/G10 | J16901PC/G30 |

|---|---|---|---|---|---|---|

| Tensile Strength | MPa | ISO 527-2 | 57.8 | 62.9 | 90 | 62 |

| Tensile Elongation | % | ISO 527-2 | 20.2 | 9.8 | 5 | 0.8 |

| Flexural Strength | MPa | ISO 178 | 91.8 | 101.2 | 141.9 | 97 |

| Flexural Module | MPa | ISO 178 | 3736 | 3827 | 3900 | 7202 |

| Charpy Notch Impact | KJ/m2 | ISO 179-1 | 17.5 | 10.2 | 9 | 11.8 |

| Mass Density | g/cm3 | ISO 1183 | 1.265 | 1.255 | 1.273 | 1.409 |

| 熔流体速率 | g/10min | ISO 1133 | 8.2 | 18.4 | 12.2 | – |