|

Plastic Molding in China |

|

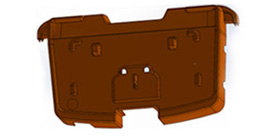

Plastic Cover of a Medical Device

Product Description

Our client is one of the largest medical device distributors in the Central Europe and CIS markets. This plastic product was cover used in ambulance manufacturing, which had high appearance requirements.

Product Requirements

The specific requirements of the product are as follows:

ASA+PC fireproof (UL94-V0), UV-resistant white, RAL 9016 and smooth surface required.

The dimensions must fully matched the requirements on drawings.

All the ribs on the back must not be out of material.

No shrinkage is on the front appearance.

The product must not have any deformation, mottled parts, burrs or other injection defects.

Mold Requirements

Mold Name: Injection Mold

Mold Manufacturing Processes: CNC Machining, EDM, and WEDM

Mold Material: P20 Steel

Number of Cavities: One

Mold Design of Plastic Cover

Mold Design Review

1. Injection Gate

Concerning about the high requirements for product flatness, there were two pin point gates on the front of the cover and nine inclined lifters and several sleeves on the back in the original design , as shown below:

Front

Back

However, the client rejected the design because this surface was not allowed to put pin point gates, which affected the appearance of the product. The pin point gates was asked to become side gates. In fact, this product was so big with nine inclined lifters on back. The inclined lifters would be easily damaged if we chose the side gates in the mass production. At the same time, the product would have the risk of the occurrence of return lines in injection molding. And, the wall thickness of bottom ribs was thin and hard to be filled completely.

Mold Flow Analysis based on client’s design

We provided a better solution that making two pin point gates with hot runner to reduce the occurrence of return lines. In this way, the product could be filled totally. Finally, we got the approval from our client.

Mold Flow Analysis based on our design

2. Inclined Lifters

Inclined lifter interference was requested according to customer's original drawing requirements. Considering the operation in production, we advise the client to cut the ejection distance of the inclined lifters and remove the size blue parts which are shown as below.

Blue Parts suggested to be removed

After communication, the client accepted our recommendation to modify the structure to shorten the ejection distance of the inclined lifters.

3. Making Mold

When we tested the mold capability, it was found that three of inclined lifters were broken totally in two trial production. We analyzed the root causes, as following reasons:

The strength of the inclined lifters was not enough.

Product ejection force was strong and unbalanced.

The material of inclined lifter was poor.

Design Analysis

Broken inclined lifter

Then, facing the problems, we improved the mold design within three aspects:

The product continues to be polished at the tendons to reduce the product ejection force.

Replaced P20, the original material of inclined lifters, with SKD61.

Added 34 dome rods to reduce the ejection force and made anti-slip grooves on the end of the rods.

After the implementation of the improvement, all defects had been resolved.

The finished Product

In Conclusion

This project highly illustrated that a good product could not come out without a close cooperation between product developers and manufacturing engineers. After full communication, we can absolutely figure out how to help customers solve problems in the design and ultimately manufacture products with customer requirements.